Solar energy has seen a huge increase in the last few years. People are installing solar panels in their houses to become more energy efficient. Whether you are thinking about installing solar panels or have seen someone installing them, there may be some questions you are curious about.

One such question many people ask is what solar panels are made of. Along with this, several queries and worries related to the solar panel manufacturing process have arisen.

If you want to install a solar panel in your house, you must get all your queries answered. The guide answers the question – what are solar panels made of? It also covers other queries that you may have about the solar panel manufacturing process.

Contents

- 1 Key Takeaways

- 2 What are the Components of a Solar Panel?

- 3 What Are The Parts Present In A Solar Panel?

- 4 Types of Solar Panels

- 5 How Are Solar Panels Made?

- 6 Is The Manufacturing Process Of Solar Panels Environment Friendly?

- 7 Is It Dangerous To Live Nearby A Solar Farm?

- 8 What Are The Toxic Materials Present In A Solar Panel?

- 9 Case Study: Understanding the Composition and Environmental Impact of Solar Panels

- 10 Expert Insights From Our Solar Panel Installers About Solar Panel Composition

- 11 Discover the Power of Solar with Solar Panels Network

- 12 Summing Up

Key Takeaways

- Solar panels are primarily made of crystalline silicon wafers, with about 95% of panels using silicon as semiconductors. Other components like wiring, metal, glass, and plastic contribute to power generation.

- There are three main types of solar panels: monocrystalline, polycrystalline, and thin film solar cells, each with advantages and disadvantages.

- The manufacturing process of solar panels has become more environmentally friendly over the years, but it still emits carbon dioxide. Toxic materials in panels are only hazardous during manufacturing, not operation.

What are the Components of a Solar Panel?

Solar panels are energy efficient and produce environmentally friendly energy. They use a renewable energy source –solar power, that we have an endless supply of. These panels are made from several materials and components.

The main component of most solar photovoltaic panels is crystalline silicon wafers. Almost 95% of solar panels use silicon to create semiconductors—the rest of the 5% use in-development and experimental technologies such as organic photovoltaic cells.

The electricity you get through the solar panels is derived from semiconductors. They come in contact with sunlight, and the electrons present in the semiconductors become loose. It produces electricity, and the process is known as the photovoltaic effect.

However, the photovoltaic cells are not the only component that helps provide to your house. Other components such as wiring, metal, glass, and plastic produce power.

The solar cells used in solar panels are ideally sensitive to sunlight. Solar panels have a glass layer and an anti-reflective coating to protect these solar cells. However, the coating and glass layer let sunlight enter the cells.

The solar panel system is mounted on a polymer or plastic frame during installation. They can either be ground-mounted or installed on your rooftop.

What Are The Parts Present In A Solar Panel?

As mentioned above, solar panels are made from several components. The below section provides an overview of those components.

Silicon Solar Cells

Silicon solar cells are the components that use the photovoltaic effect to convert solar power into electricity. The structure of the solar cells is like a matrix and is bound together between glass panels. These silicon solar cells create electric charge by interacting with the glass wafer sheet.

Metal Frame

The metal frame of a solar panel is ideally made from aluminium and helps with several things. It prevents the solar panel from getting damaged by dangerous situations or harsh weather conditions. The frame is also helpful in mounting the solar panel at your preferred angle.

Standard 12V Wire

The 12V Wire helps regulate the energy transferred to your inverter. It helps in making the solar panel system more efficient and sustainable.

Bus Wire

The solar silicon cells are connected parallel to the panels using the bus wires. They have a thin solder layer that helps in soldering. Moreover, the bus wires are thick enough to pass on the electric currents.

Glass Sheet

The glass sheet in the solar panels is usually six to seven millimetres thick. This is quite thin, but they help protect the silicon solar cells in the solar panel system.

Types of Solar Panels

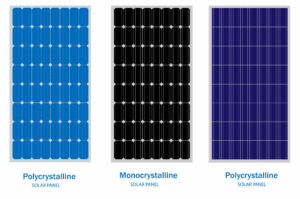

Like most products, solar panels also come in different types and forms. Below are the three types of solar panels that you will come across.

Monocrystalline Solar Cell

Monocrystalline solar panels are made from a single silicon block. They are produced as silicon wafers. The manufacturing process includes cutting silicon into the wafer and attaching them to the solar panel.

Monocrystalline solar panels are said to be more energy-efficient than amorphous solar cells or polycrystalline cells. However, creating individual wafers of monocrystalline cells is very labour-intensive.

Due to this, monocrystalline is said to be more expensive than any other type of solar panel. There is a significant black aesthetic to these cells; they are also very sleek.

Polycrystalline Solar Cell

Another type of solar panel is the polycrystalline solar panel. These solar panels are divided into wagers, and they are made from melting several silicon crystals. The manufacturing process involves melting the silicon molecules and reusing them to form the panel.

Polycrystalline solar cells are not as efficient as monocrystalline solar cells. However, since they are less efficient, they are also less expensive than monocrystalline solar cells. These solar panels have a bluish colour that makes them seem very aesthetic.

Thin Film Solar Cells

Thin film solar panels are made of amorphous silicon and are quite flexible. From the name, it is clear that these solar cells have a thin texture. Thin film solar cells do not have a crystal formation and are attached to metal, plastic, or glass substrates.

Even though amorphous silicon cells are very versatile, they are not as efficient as poly or monocrystalline cells.

How Are Solar Panels Made?

The solar panel manufacturing process starts with the creation of silicon cells. This process includes melting the silicon and mixing it with other supporting elements. Then, different sheets are cut to turn them into component cells.

The process involves mass production as well as laser cutting. These finished cells are protected using a layer of plastic or glass.

After creating the solar cells, they are connected in the right configuration, shape, and size. To do this, these are soldered to the solar panel’s base. This base is made from a conductive metal essential for electricity production.

The next step is to connect the system to a polymer frame. This holds the system and insulates all the electrical components. It covers all the components using a protective glass layer. The final step involves boxing all the panels and sending them to the installers.

Is The Manufacturing Process Of Solar Panels Environment Friendly?

Solar energy is a clean energy source, but the manufacturing process is not as clean. Severe improvements in the solar panel manufacturing process have ensured less environmental pollution.

According to an academic study, there has been a downward slope in the environmental impact of solar panel manufacturing between 1975 and 2015. This downward slope has not stopped in years, and manufacturers have developed more environmentally friendly solutions.

Solar producers are trying to find environment-friendly solar production and materials. They are also searching for ways to recycle the panels and their components. This minimizes the harsh impacts that solar panels have on the environment.

That being said, the production of solar panels emits harmful carbon dioxide into the environment. This is what renewable energy sources are trying to curb. The same happens for other renewable energy sources, such as wind turbines and power plants.

However, the environmental impact has been divided since solar panels have extended longevity.

Is It Dangerous To Live Nearby A Solar Farm?

A solar farm is a large piece of land with several solar panels that help generate electricity on a large scale. Solar farms do not emit any toxic chemicals, noise, or pollution that would cause a hazard to the environment.

The hazardous materials in the solar panels are contained within them. They are not emitted during usage, which leads to the production of clean energy. However, the issue arrives when the solar panels are disposed of or recycled.

It should be done in an area that does not have a livelihood nearby.

What Are The Toxic Materials Present In A Solar Panel?

Certain materials in the solar panels are very toxic to the environment and people. These include selenium, copper, arsenic, cadmium telluride, or hexavalent chromium coating. However, these materials are only toxic during the manufacturing of solar panels.

These materials have no impact once the solar panels are taken into operation. This is because the materials are contained within the solar panel. It does not get activated when the panel comes in contact with sunlight.

Therefore, the energy we get is clean, efficient, and sustainable.

Case Study: Understanding the Composition and Environmental Impact of Solar Panels

Background

Solar Panels Network was approached by a homeowner in Essex looking to install a solar energy system. The client was interested in understanding the materials used in solar panels and their environmental impact. They wanted assurance that the panels were efficient, durable, and as eco-friendly as possible. Our objective was to provide a detailed overview of the solar panel components and the sustainability of their manufacturing process, aligning the installation with the client’s environmental values.

Project Overview

The project involved selecting and installing a solar panel system that met the client’s energy needs while adhering to their environmental concerns. This required a thorough explanation of the materials used in solar panels, their sourcing, and the overall sustainability of the manufacturing process.

Implementation

- Material Selection and Explanation: We provided the client with comprehensive information on the types of silicon used in solar panels—monocrystalline, polycrystalline, and thin-film—and their respective efficiency and environmental impacts. This included:

- Monocrystalline Silicon: High efficiency, long lifespan, but more resource-intensive to produce.

- Polycrystalline Silicon: Lower cost and moderate efficiency, with a less intensive manufacturing process.

- Thin-Film Solar Cells: Flexible and lightweight, though less efficient, offering easier integration into various applications.

- System Installation: The selected monocrystalline panels were installed, prioritising efficiency and durability. Key steps included:

- Mounting and Framing: Using high-quality aluminium frames for stability and durability.

- Electrical Integration: Incorporating bus wires and a high-efficiency inverter to optimise energy conversion and distribution.

- Protective Measures: Installing tempered glass covers and anti-reflective coatings to protect the panels and enhance performance.

- Environmental Considerations: Emphasising the importance of sustainable practices, we sourced panels from manufacturers committed to reducing the environmental impact of their production processes. This included:

- Eco-Friendly Production: Choosing manufacturers that utilise renewable energy in production and adhere to strict environmental regulations.

- Toxic Material Management: Ensuring the panels contained minimal toxic materials, with proper disposal plans in place for end-of-life management.

Results

- Energy Efficiency: The monocrystalline panels delivered high efficiency, providing sufficient energy for the household’s needs and reducing reliance on the grid. Environmental Impact: The chosen panels had a reduced environmental footprint due to the eco-friendly manufacturing processes and responsible sourcing of materials.

- Cost Savings: The client experienced significant savings on energy bills, with the high-efficiency panels ensuring optimal performance and a quick return on investment.

- System Longevity: The high-quality materials and robust installation ensured a long lifespan for the system, with minimal maintenance requirements.

Summary

The project successfully met the client’s dual objectives of efficiency and environmental responsibility. By choosing monocrystalline silicon panels and focusing on sustainable manufacturing practices, we provided a high-performing, durable solar energy solution. The client’s energy needs were met while minimising environmental impact, demonstrating the viability of eco-friendly solar panel installations. Solar Panels Network continues to advocate for sustainable energy solutions, ensuring our clients benefit from both financial savings and reduced carbon footprints.

Expert Insights From Our Solar Panel Installers About Solar Panel Composition

Knowing what goes into solar panels is essential for understanding their efficiency and durability. The use of high-quality silicon and protective glass layers ensures that these panels not only last longer but also perform optimally in various weather conditions.

Senior Solar Installer

The materials used in solar panels, particularly the type of silicon, significantly influence their performance. As technology advances, we’re seeing improvements in both the efficiency and environmental impact of these materials, making solar energy an even more viable option.

Renewable Energy Consultant

While the production of solar panels does involve some potentially hazardous materials, these are safely contained within the panels during operation. Our priority is to ensure that these products are safe for both users and the environment.

Lead Solar Technician

Discover the Power of Solar with Solar Panels Network

Are you navigating the world of solar installations? Look no further than Solar Panels Network, the UK’s trusted partner in harnessing the sun’s potential. Our dedication goes beyond just installations; we’re on a mission to transform how homeowners and businesses across the UK perceive and utilise energy. By choosing us, you’re reducing your carbon footprint and making a smart financial move that promises savings for years ahead. Contact us today and embark on your solar journey.

Summing Up

From the above guide, it is clear that a solar cell is made of silicon in different shapes, sizes, and textures. This helps produce energy and provide electricity to your house. However, the production process of a solar panel is not as clean as its energy.

Solar panels consist of several toxic components which are harmful to the environment. That said, the operating solar panel system releases no harmful environmental toxins. Moreover, solar producers continually search for more refined and environment-friendly components to manufacture solar panels.

Solar manufacturing plants need to be as far away as possible from the population. This will help keep people safe from these toxins and help them get clean energy.

About the Author

Solar Panels Network stands at the forefront of solar energy solutions, driven by a team of seasoned solar engineers and energy consultants. With over decades of experience in delivering high-quality solar installations and maintenance, we are committed to promoting sustainable energy through customer-centric, tailored solutions. Our articles reflect this commitment, crafted collaboratively by experts to provide accurate, up-to-date insights into solar technology, ensuring our readers are well-informed and empowered in their solar energy decisions.