The production of solar panels is a captivating process that transforms sunlight into a sustainable source of energy. In this article, we will delve into the intriguing world of solar panel manufacturing, unveiling the intricate steps and materials involved in creating these remarkable devices. Discover the secrets behind the production of solar panels and gain a deeper understanding of this vital component of renewable energy technology.

Contents

- 1 Key Takeaways

- 2 The Popular Solar Panel Types: What Are They?

- 3 What are the Different Components of a Solar Panel?

- 4 How Solar Panels are Made – Explained

- 5 Why is Silicon Important in Solar Panels?

- 6 Which Companies Manufacture Solar Panels in the UK?

- 7 Case Study: Enhancing Residential Solar Installations with Advanced Solar Panels

- 8 Expert Insights From Our Solar Panel Installers About How Solar Panels Are Made

- 9 Discover the Power of Solar with Solar Panels Network

- 10 Final Thoughts

Key Takeaways

- The UK relies heavily on solar panels, with various types available, including monocrystalline, polycrystalline, and thin-film panels, each with advantages and disadvantages.

- Regardless of type, solar panels consist of key components such as solar cells, solar glass, EVA sheet, back sheet, aluminium frame, junction box, and silicon glue, which work together to harness solar energy.

- Manufacturing solar panels involves several steps, including silicon extraction from sand, ingot production, wafer assembly, solar cell formation, panel assembly, testing, and inspection before shipping.

The Popular Solar Panel Types: What Are They?

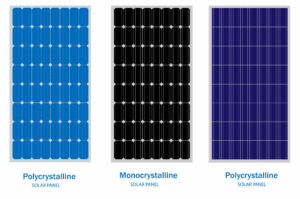

While many types of solar panels are available for sale today, three are most common across the UK: monocrystalline, polycrystalline, and thin-film solar panels. So, what are they, and what sets them apart?

Monocrystalline Solar Panels

Also known as Mono-SI, this type of solar panel is renowned for being one of the purest panels. Their dark appearance and round edges characterise them. The best part is that the monocrystalline solar panels have many benefits:

- High-efficiency rate, over 20%

- High power output

- Long-lasting

- Require less space for installation and maintenance

- Can endure high temperatures

Polycrystalline Solar Panels

With square edges and a distinct blue appearance, the Poly-SI panels are easy to distinguish. They make use of melted silicon. You can expect the following benefits from polycrystalline solar panels:

- Their efficiency is pegged at 15%

- They are cheaper than Mono-SI panels

However, there are significant downsides associated with them as well. For instance, they do not function well under high temperatures and are not big on space efficiency.

Both Mono-SI and Poly-SI panels are classed as first-generation solar panels.

Thin Film Solar Panels

A second-generation offering, thin-film solar panels, is produced by juxtaposing multiple photovoltaic films onto a base. There are many benefits that thin-film solar panels bring to the table, such as:

- Easy production

- Cost-effective

- It can be integrated with other systems

- Perform well under high temperatures

Their advantages notwithstanding, the issue with thin-film solar panels is that they take up much space, making them unsuitable for residential use. Likewise, their short warranty span makes them unfeasible for long-term usage.

What are the Different Components of a Solar Panel?

Irrespective of its type, a solar panel is generally comprised of the following parts:

- Solar Cells: The efficiency of a solar panel is determined by the solar cells. Solar cells can be monocrystalline or polycrystalline depending on the type of solar panel being produced.

- The Solar Glass: The solar glass is a solar panel’s outer protective layer. The sturdier the glass, the better the performance. It shields the panel from inclement weather conditions and prevents the accumulation of dirt.

- An EVA Sheet: The solar cells need to be held together. That is where an EVA sheet comes in. The sheet also doubles up as a transparent and laminated layer that can provide the solar panel with added protection.

- Back Sheet: Like the EVA sheet, a back sheet is also meant to protect the solar panel. Additionally, the sheet offers electrical insulation.

- Aluminium Frame: The frame equips the solar panel with structural support and aids in holding the solar cells together

- Junction Box: As the name suggests, a junction box is where all the cables meet and connect with the solar panel

- Silicon Glue: The glue functions as a super adhesive that can hold the solar cells together, while its conductive and convective properties facilitate power generation

How Solar Panels are Made – Explained

How do the various parts of a solar panel come together? See for yourself in the step-by-step guide that follows:

Step 1: Silicon Extraction from Sand

Silicon is a crucial element in solar panels. While the element is abundantly available in sand, extracting it from sand is complex and expensive. For this purpose, quartz sand is used, which contains a generous amount of natural silicon deposits.

The quartz sand is treated in a furnace at high-temperature conditions.

Step 2: The Production of Ingots

After extracting silicon from quartz sand, the rocks are melted under high temperatures to produce ingots. These nuggets are central to the working of solar panels. Usually, they are cast in cylindrical shapes, emphasising the overall structure.

At times, trace amounts of Boron are added to the ingots to boost the conductive properties of silicon.

The ingots are obtained from melting a single silicon crystal for monocrystalline solar panels. On the other hand, for polycrystalline panels, numerous silicon crystals are melted to produce ingots.

Step 3: The Assembly of Wafers

The ingots are cut and shaped into thin wafer-like or disc-like forms in this step. Specific tools are used to achieve the maximum possible thinness in wafer width.

After the cutting, a robust anti-reflective coating is applied to the wafers to minimise the heat lost due to silicon’s powerful reflective nature.

Step 4: From Wafers to Solar Cells

Once the solar wafers are ready, they are fitted with conductors. Consequently, the wafers can be arranged in grid formations, increasing the surface area for solar energy absorption and conversion into electricity.

At this juncture, the solar cells are coated with a layer of Phosphorus. Considering that the cells were already covered with Boron during the production of ingots, they developed the P-N junction, the USP of solar panels.

Step 5: Formation of Panels

Solar cells undergo complete soldering, after which they get interlinked through connectors. A glass layer is placed on the side facing the sun, while a back sheet is on the opposite side.

A junction box is installed, and all the parts are arranged inside the frame. Finally, mounting clamps mount the frame on the household’s rooftop.

Step 6: Final Steps

The assembled solar panels are tested against industry standards to ensure their efficiency. Their performance is monitored for power output, voltage, tolerance and current.

The solar panels that fulfil the performance criteria are cleaned and inspected before shipping.

Why is Silicon Important in Solar Panels?

Silicon has many properties that make it perfect for use in solar panels. Some of them include:

- It has excellent electronic, thermal and optical properties

- Silicon is widely available and easy to procure

- When compared with other elements, silicon is more affordable

- It has an incredible sunlight-absorbing capacity

- Has optimum semiconducting properties

- The silicon P-V junction is effective

Which Companies Manufacture Solar Panels in the UK?

While the leading solar panel manufacturers are based in Asia and Germany, the UK has a fair share of solar panel manufacturers.

Generally, these companies import photovoltaic cells and assemble them into panels at their factories in the UK.

- GB-SoI: Based out of Wales, they manufacture solar PV panels for off-grid systems and cater to domestic, residential and commercial installations. They have held their own in the solar energy industry for over 20 years and are still going strong.

- Viridian Solar: This company from Cambridge manufactures rooftop solar panel installations, making them renowned.

- Romag: Established in 1943, Romag is a company that dabbles with many things solar. They have done everything from supplying solar panel products BIPVs to producing Inteco solar tiles. They have established a strong presence across North East England.

- Solarcentury: They are known for two of their products – solar tiles known as C21e and a BIPV-style product called SunStation. Their primary operations are in London.

- AES Solar: AES Solar is a company from Scotland renowned for its reputation as one of Europe’s oldest solar panel manufacturers.

Polysolar, SunSolar Energy and Solion are the other big names that headline the solar panel manufacturing scene in the UK.

For installing solar panels at your residence or office building, contact only the solar panel installers whom the MCS has approved. In this way, your household will become eligible for the UK government’s feed-in tariff income scheme.

Case Study: Enhancing Residential Solar Installations with Advanced Solar Panels

Background

Solar Panels Network is dedicated to providing homeowners with cutting-edge solar technology, ensuring they harness the maximum potential of solar energy. In a recent project, we worked with a residential client to upgrade their existing solar setup with new, more efficient solar panels. This case study explores our approach to optimising residential solar installations, focusing on enhancing energy efficiency and cost savings for homeowners.

Project Overview

The project aimed to replace an older, less efficient solar panel system with state-of-the-art monocrystalline panels. Our goal was to significantly improve the energy output and reliability of the system, providing the homeowner with substantial long-term savings on their energy bills. Additionally, we sought to educate the homeowner on the benefits of the new technology and ensure a smooth transition from the old system.

Implementation

- Site Assessment and Planning: We conducted a thorough assessment of the property’s roof orientation, shading, and structural integrity. This evaluation helped us determine the optimal placement and angle for the new solar panels to maximise sun exposure.

- Selection of Monocrystalline Panels: Based on the homeowner’s energy needs and budget, we recommended high-efficiency monocrystalline panels. These panels offer superior energy conversion rates and durability, making them ideal for residential use.

- Installation Process: Our team of certified installers carefully removed the old panels and installed the new monocrystalline system. We used high-quality mounting hardware to ensure the panels were securely attached and optimally positioned.

- System Integration and Testing: We integrated the new panels with the existing solar inverter and electrical system. After installation, we conducted comprehensive testing to ensure the system was operating at peak efficiency and safely connected to the grid.

- Homeowner Education: We provided the homeowner with a detailed overview of the new system’s features, including energy monitoring tools, maintenance tips, and the benefits of their upgraded setup.

Results

- Increased Energy Output: The new monocrystalline panels increased the system’s energy output by approximately 25%, allowing the homeowner to generate more electricity and reduce reliance on the grid.

- Cost Savings: The enhanced efficiency of the new panels resulted in a noticeable reduction in monthly energy bills. The homeowner is expected to recoup their investment in the upgraded system within 5-7 years through savings on electricity costs.

- Improved Aesthetic and Value: The sleek design of the new panels improved the home’s aesthetic appeal and potentially increased its market value, making it an attractive feature for future buyers.

- Environmental Impact: The new system’s improved efficiency contributes to a reduced carbon footprint, aligning with the homeowner’s commitment to sustainable living.

Summary

The successful upgrade of the residential solar installation demonstrates the significant benefits of advanced solar panel technology. By replacing outdated panels with high-efficiency monocrystalline options, Solar Panels Network enabled the homeowner to achieve greater energy savings, enhance the property’s value, and contribute positively to the environment. Our comprehensive approach ensured a seamless transition and maximised the system’s performance, reaffirming our commitment to delivering top-tier solar solutions for residential clients.

Expert Insights From Our Solar Panel Installers About How Solar Panels Are Made

Understanding the manufacturing process of solar panels gives us a deeper appreciation of the technology. The precision in silicon wafer production and the intricate assembly process ensure that each panel maximises efficiency and durability.

Lead Solar Panel Installer

Solar panels are a marvel of modern engineering, with each component playing a critical role. From the EVA sheets to the junction box, every element is meticulously crafted to ensure optimal energy conversion and longevity.

Solar Energy Specialist

The use of high-purity silicon in monocrystalline panels is particularly fascinating. It not only enhances efficiency but also ensures that these panels can withstand extreme weather conditions, making them ideal for the UK climate.

Senior Technical Engineer

Discover the Power of Solar with Solar Panels Network

Are you navigating the world of solar installations? Look no further than Solar Panels Network, the UK’s trusted partner in harnessing the sun’s potential. Our dedication goes beyond just installations; we’re on a mission to transform how homeowners and businesses across the UK perceive and utilise energy. By choosing us, you’re reducing your carbon footprint and making a smart financial move that promises savings for years ahead. Contact us today and embark on your solar journey.

Final Thoughts

Producing solar panels is a captivating process that unlocks the potential of transforming sunlight into sustainable energy. We’ve explored the intricate steps and essential components of creating these remarkable devices, shedding light on their pivotal role in renewable energy technology. Solar panels come in various types, each with unique advantages and drawbacks, but they all share components that work harmoniously to harness solar energy effectively.

The manufacturing process involves extracting silicon from sand, ingot production, wafer assembly, solar cell formation, panel assembly, rigorous testing, and inspection. Silicon’s exceptional properties make it an ideal material for solar panels, with its electronic, thermal, and optical qualities, wide availability, affordability, and sunlight-absorbing capacity. Several reputable solar panel manufacturers in the UK contribute to the country’s solar energy industry, offering options for residential, commercial, and off-grid installations. To make the most of solar energy in the UK, working with MCS-approved solar panel installers is essential, ensuring quality installations and eligibility for government incentives. Understanding the production and utilization of solar panels is vital as the world continues to embrace renewable energy sources for a sustainable and greener future.

About the Author

Solar Panels Network stands at the forefront of solar energy solutions, driven by a team of seasoned solar engineers and energy consultants. With over decades of experience in delivering high-quality solar installations and maintenance, we are committed to promoting sustainable energy through customer-centric, tailored solutions. Our articles reflect this commitment, crafted collaboratively by experts to provide accurate, up-to-date insights into solar technology, ensuring our readers are well-informed and empowered in their solar energy decisions.